Create a robot solution in days instead of months or years

With our Modular Open Robot Platform Hardware you'll get a working mobile robot capable of navigation and 3D obstacle avoidance. The platform can be adapted to your applications needs and we can assist in rapid development of your robotic solution.

Modular Open Robot Platform Hardware

fully modular

from the frame to the electronics to the shell, everything is modular and can be adapted for your solution needs

mobile robot platform supports 100KG load

differential drive powerful robot platform

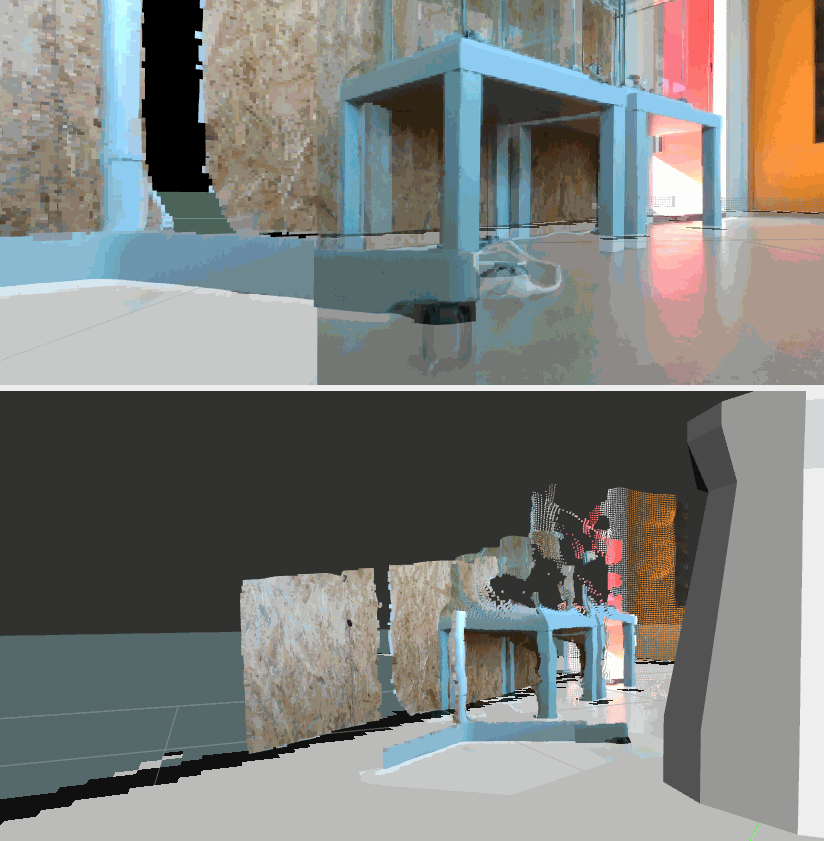

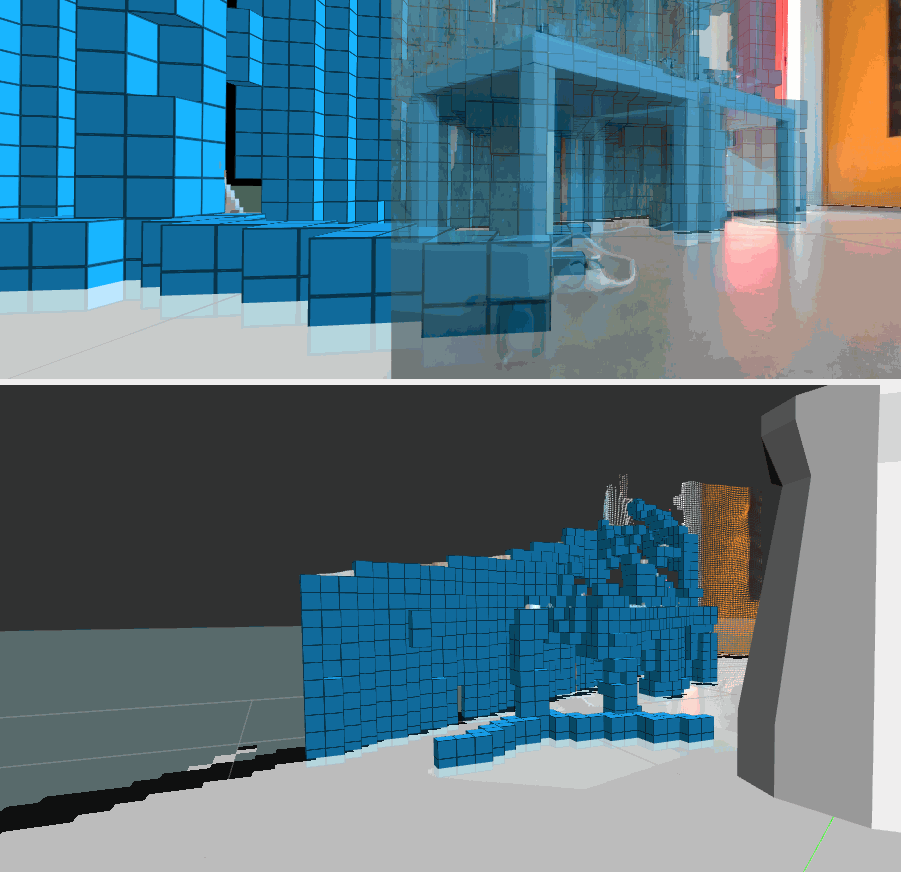

navigation and obstacle avoidance

SLAM (simultaneous localization and mapping) with obstacle avoidance powered by ROS

Silent motors

powerful brushless hub motors ensure silent operation without gear noise

multiple safety features

fused power distribution, battery protection circuits, on-board power restrictions and under voltage protection to name a few

open technology

no-vendor lock-in, open source software and hardware

MORPH M1 Series standard configurations

Start with a standard configuration or customize from scratch, it's both possible!

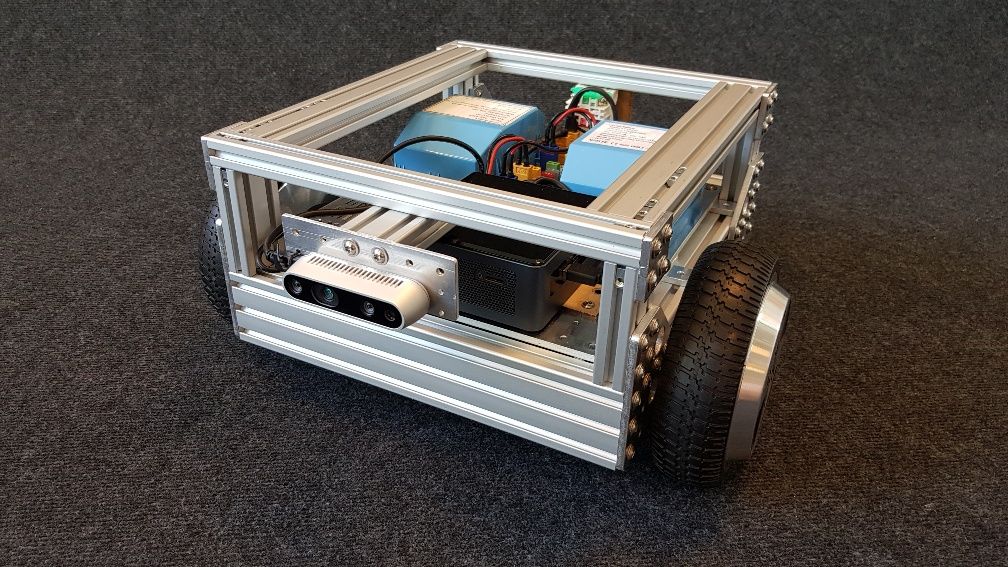

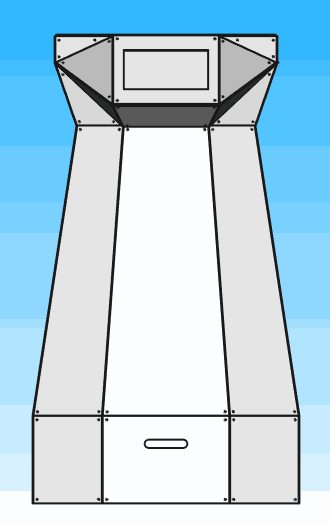

M1 Core Base

For development or learning purposes the mobile base contains what you need to get started in robotics. The base can be provided with or without cover

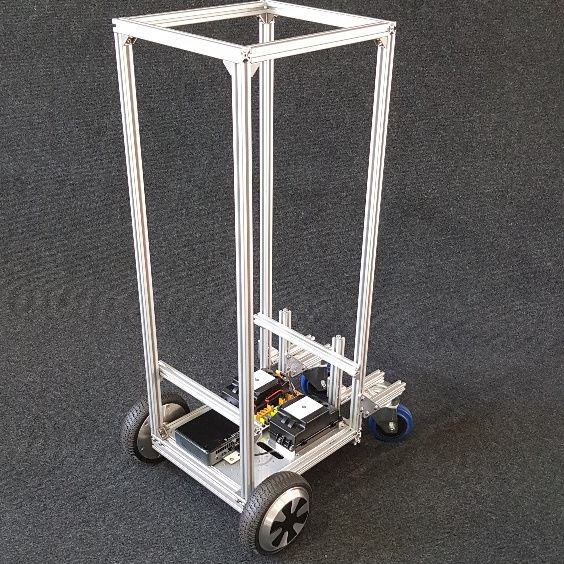

M1B1 butler robot

Designed to bring your drinks or small packages, the butler robot has social interaction possibilities with integrated microphone array, touch screen and speakers

Customized frame

The robot can be fully adjusted to your robotic solution needs with a custom frame

Fully modular open robot platform

Modular and open in all aspects

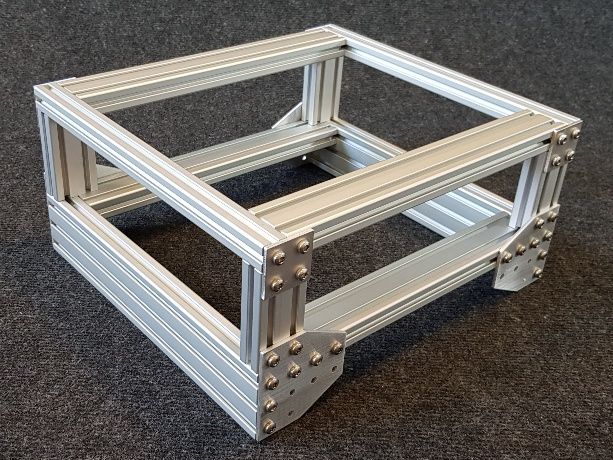

Fully modular frame - modular at the core

-

The frame is built around T-slot system profiles and can be adjusted in every dimension

-

Modular system panels allows future expansion or replacement of electronics and sensors

Fully modular Electronics

-

Increase battery capacity by adding additional battery modules

-

Add sensors depending on the application needs

-

Choose computing power according to your application needs

-

System panels with standard holes grid pattern

-

Mounting holes are threaded for easy and fast assembly also preventing issues with nuts coming loose due to vibrations

Fully modular cover

-

The cover is designed to allow rapid small and medium scale manufacturing using rapid prototyping techniques such as 3D printing and lasercutting

-

Individual panels can be replaced easily, allowing easy changes for example to add additional sensors

-

Iterate your robot design much faster

-

The cover can be fully customized to your needs, changing dimensions, cut-outs for sensors or other features and optionally covered with a printed vinyl wrap

Robotic services

Rapid prototyping service

Save time and launch your product quicker. We can help prototype your solution in our own innovation lab. We can work with partners to integrate with social robotics and other custom solutions.

Software development

Developing robotics software with open technology

ROS / OpenCV / C++ / Python and more

Support, care packages and training

Making sure everything keeps working as needed and providing assistance when needed

Application design example: robotic butler

Brings your drinks and food with social interaction

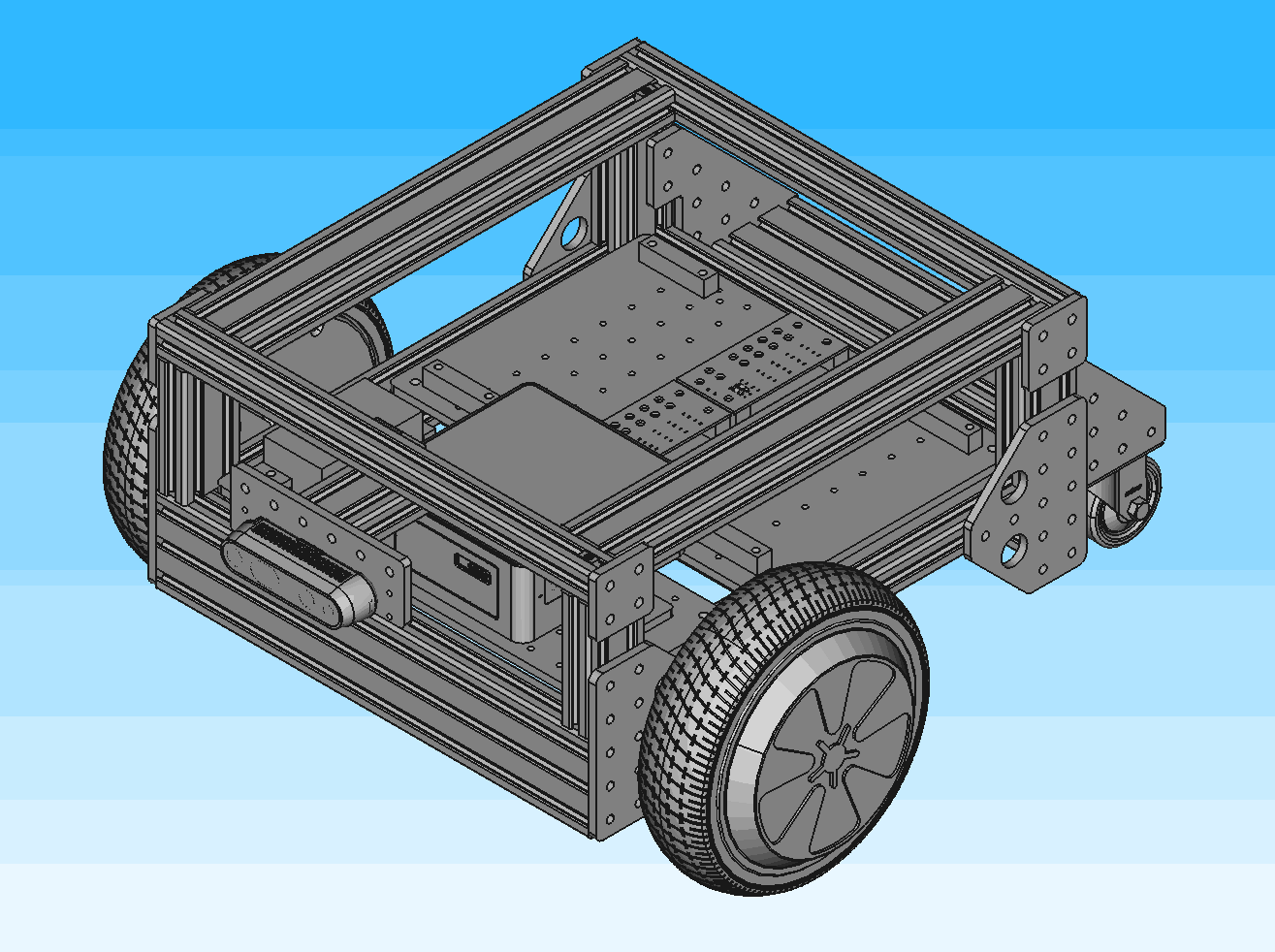

Start with platform design

Depending on the solution we determine start with the mobile base for the robot and determine the frame size. The standard frame supports up to four battery modules and can fit a compact computing unit powerful enough for most applications. The design is first created in CAD and validated with the customer before assembly begins.

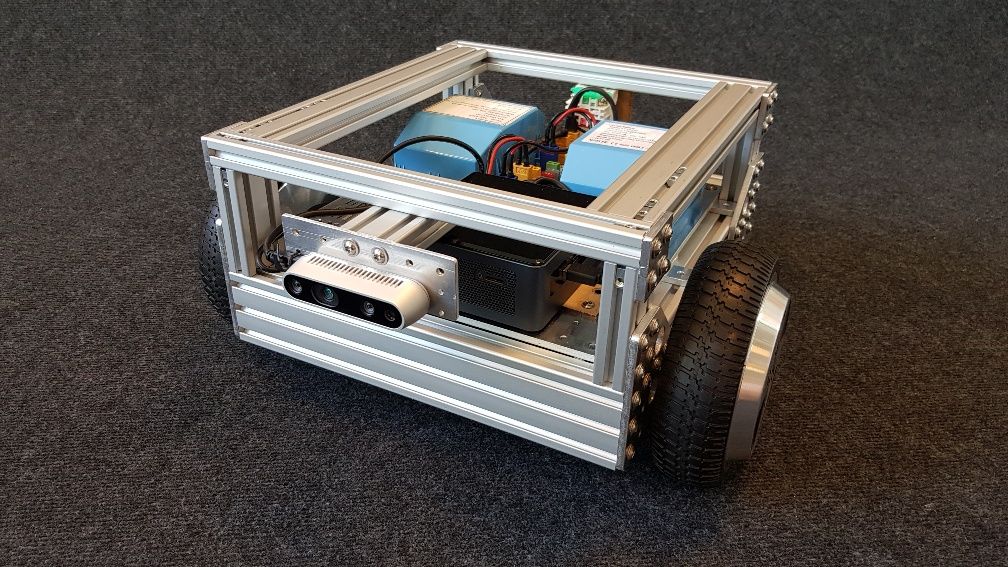

To reality

With the platform base design finished, we can start the assembly of the robot base. Because of the modular structure assembly is quick and easily changed if needed.

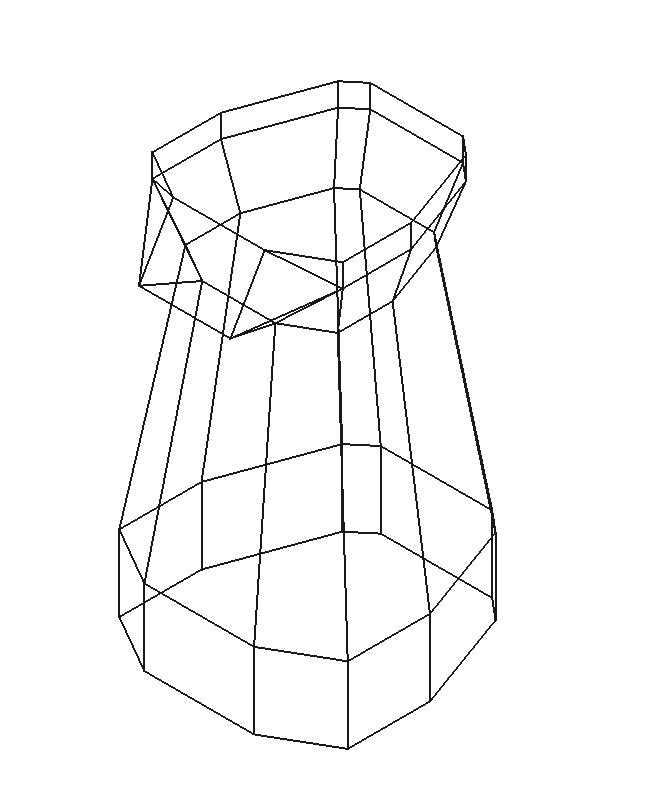

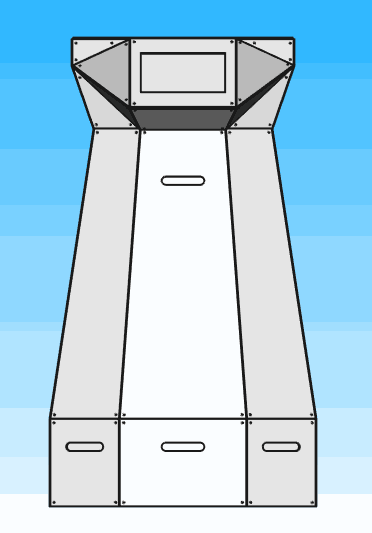

Customized modular cover - start with global design

First a global design for the robot is created. Based on the application requirements such as height and robot footprint restrictions. For the robot platform the height is chosen to be able to pick-up a tray from the top while seated at a table. Additionally a feature is added to mount a touchscreen for interaction with the robot.

We have developed a way to create a customized modular cover which can be manufactured at small to medium scale without the huge startup cost. This way the design of your robot can be developed on a iterative basis. The basis of this design is a low-poly based 3D structure of flat panels joined by brackets. This way we can utilize rapid prototyping techniques like lasercutting, CNC-routing and 3D printing. This technique is scalable for a single or small-scale to large scale. This way the design can be tested and updated without having to spend large setup costs on other manufacturing techniques.

Customize: add sensors and touchscreen

Customizations can be applied to the global design, such as cut-outs for sensors or touchscreen. With our generative CAD software the design for panels and brackets are generated.

.

A first prototype

The panels can be cut using a lasercutter or CNC machine. Brackets are 3D printed and an optional wrap is applied with a custom style or logo. The prototype can be created quickly without a lot of cost so you can test ideas very quickly.

Iterate your design

After testing you may find out you need more or different sensors. Or maybe the position of the sensors should be changed. With our modular cover you can make changes to the cover and replace individual panels without having to replace and recreate the complete cover. This saves cost and valuable time and allows you to do rapid iterative prototyping.

Updated prototype with additional depth cameras

For better navigation and obstacle avoidance additional depth cameras are added. This increases the field-of-view. Also a different model is selected which has an increased range of up to 20m (instead of 10m). A test drive at client's location

Perception: multiple depth cameras for wide field of view